- Cause: You use a low speed connection or the Internet is slow at this time. Solution: Hit the Refresh Button of the browser.

- Cause: Your browser is not complying with the cascading style sheet used. Solution: Update your browser. We recommend Internet Explorer (IE) or FireFox.

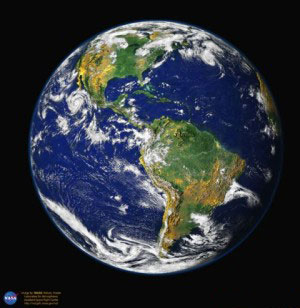

Terra* viewed from space. Photo courtesy of NASA. Quote We should not say 'I am an Athenian' or 'I am a Roman' but 'I am a Citizen of the Universe'. Marcus Aurelius |

|

Advantages of Carbide Burrs over Other Cutting ToolsCarbide burrs offer several advantages over other cutting tools used in metalworking. VersatilityCarbide burrs are highly versatile and can be used to grind and shape a wide range of metal components. They come in a variety of shapes and sizes to suit different applications and materials. DurabilityCarbide burrs are made from tungsten carbide, which is a very hard and durable material that can withstand high temperatures and heavy use. They are less likely to wear out or break compared to other cutting tools, such as high-speed steel or cobalt steel. PrecisionCarbide burrs offer a high level of precision and accuracy in grinding and shaping metal components. They can create smooth, clean cuts with minimal burrs or rough edges. EfficiencyCarbide burrs are highly efficient and can remove material quickly and effectively. They can save time and effort compared to other cutting tools, such as files or sandpaper. Tips for Effective Use of Carbide BurrsTo get the most out of your carbide burrs, follow these tips for effective use. Choose the Right BurrChoose the right carbide burr for the job. Consider the shape, size, and material of the burr, as well as the material and application of the workpiece. Using the wrong burr can result in poor performance and damage to the workpiece. Use Proper Speed and PressureUse the proper speed and pressure when using carbide burrs. Too much speed or pressure can cause the burr to overheat or break, while too little speed or pressure can result in poor performance and slow progress. Follow the manufacturer’s recommendations for speed and pressure. Use Cutting FluidUse cutting fluid when using carbide burrs. Cutting fluid helps to lubricate and cool the burr, reducing the risk of overheating and extending its lifespan. Apply cutting fluid regularly during use. Work in a Well-Ventilated AreaWork in a well-ventilated area when using carbide burrs. The grinding process can produce dust and particles that can be harmful if inhaled. Use a respirator or other protective gear if necessary. Sharpen RegularlySharpen the carbide burr regularly using a diamond file or sharpening stone. A dull burr can result in poor performance and damage to the workpiece. Follow the manufacturer’s instructions for sharpening the burr. Clean and Store ProperlyClean the carbide burr after each use and store it properly to prevent rust and corrosion. Use a soft-bristled brush to remove any debris or metal shavings, and lubricate the burr with a light oil or cutting fluid. Store the burr in a dry, cool place in a protective case or container. ConclusionCarbide burrs offer several advantages over other cutting tools used in metalworking, including versatility, durability, precision, and efficiency. To get the most out of your carbide burrs, choose the right burr for the job, use proper speed and pressure, use cutting fluid, work in a well-ventilated area, sharpen regularly, and clean and store properly. With the right carbide burr and knowledge of how to use it effectively, you can achieve professional-quality results in your metalworking projects.

©Copyright 2022 Gabriel Ditu

|

|

Admiring the universe |