- Cause: You use a low speed connection or the Internet is slow at this time. Solution: Hit the Refresh Button of the browser.

- Cause: Your browser is not complying with the cascading style sheet used. Solution: Update your browser. We recommend Internet Explorer (IE) or FireFox.

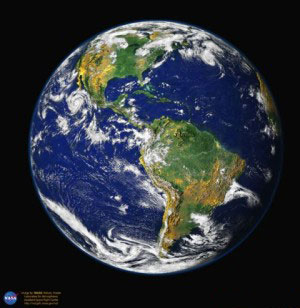

Terra* viewed from space. Photo courtesy of NASA. Quote We should not say 'I am an Athenian' or 'I am a Roman' but 'I am a Citizen of the Universe'. Marcus Aurelius |

|

In this article, we will discuss the benefits of using carbide inserts in specific machining operations, such as milling, turning, drilling, and threading. We will highlight the advantages of using carbide inserts over other cutting tools and provide specific examples of how carbide inserts can improve productivity, reduce downtime, and enhance the quality of machined components. Milling with carbide insertsMilling is a machining operation that involves removing material using a rotating cutting tool. Carbide inserts are ideal for milling operations because they offer several advantages over other cutting tools. For example, carbide inserts can withstand high cutting speeds and feed rates, which means they can remove material quickly and efficiently. Carbide inserts are also highly wear-resistant, which means they can maintain their sharpness for longer periods of time than other cutting tools. This can reduce the frequency of tool changes, which can save time and reduce downtime. In addition, carbide inserts can produce a smoother and more precise surface finish than other cutting tools, which can improve the quality of machined components. For example, carbide inserts can produce sharp corners and edges, which can be difficult to achieve with other cutting tools. Turning with carbide insertsTurning is a machining operation that involves removing material from a rotating workpiece using a cutting tool. Carbide inserts are ideal for turning operations because they offer several advantages over other cutting tools. For example, carbide inserts can cut through tough materials quickly and efficiently, which means they can reduce machining times and improve productivity. Carbide inserts are also highly wear-resistant, which means they can maintain their sharpness for longer periods of time than other cutting tools. This can reduce the frequency of tool changes, which can save time and reduce downtime. In addition, carbide inserts can produce a smoother and more precise surface finish than other cutting tools, which can improve the quality of machined components. For example, carbide inserts can produce sharp corners and edges, which can be difficult to achieve with other cutting tools. Drilling with carbide inserts

Carbide inserts are also highly wear-resistant, which means they can maintain their sharpness for longer periods of time than other cutting tools. This can reduce the frequency of tool changes, which can save time and reduce downtime. In addition, carbide inserts can produce a smoother and more precise surface finish than other cutting tools, which can improve the quality of machined components. For example, carbide inserts can produce clean holes with minimal burring and chipping, which can be difficult to achieve with other cutting tools. Threading with carbide insertsThreading is a machining operation that involves cutting a thread into a workpiece using a rotating cutting tool. Carbide inserts are ideal for threading operations because they offer several advantages over other cutting tools. For example, carbide inserts can cut threads quickly and efficiently, which means they can reduce machining times and improve productivity. Carbide inserts are also highly wear-resistant, which means they can maintain their sharpness for longer periods of time than other cutting tools. This can reduce the frequency of tool changes, which can save time and reduce downtime. In addition, carbide inserts can produce a smoother and more precise thread than other cutting tools, which can improve the quality of machined components. For example, carbide inserts can produce threads with tight tolerances and minimal burring, which can be difficult to achieve with other cutting tools. ConclusionCarbide inserts are an essential tool for modern machining operations, and they offer many benefits over other cutting tools (KoneTool Carbide Inserts, For More Details Here). Whether you are milling, turning, drilling, or threading, carbide inserts can improve productivity, reduce downtime, and enhance the quality of machined components. By taking advantage of the unique properties and capabilities of carbide inserts, machinists can achieve optimal results and deliver high-quality components to their customers.

©Copyright 2022 Gabriel Ditu

|

|

Admiring the universe |