- Cause: You use a low speed connection or the Internet is slow at this time. Solution: Hit the Refresh Button of the browser.

- Cause: Your browser is not complying with the cascading style sheet used. Solution: Update your browser. We recommend Internet Explorer (IE) or FireFox.

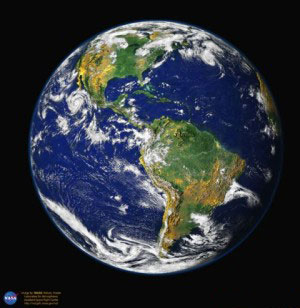

Terra* viewed from space. Photo courtesy of NASA. Quote We should not say 'I am an Athenian' or 'I am a Roman' but 'I am a Citizen of the Universe'. Marcus Aurelius |

|

Annular cutters, also known as core drills, are cutting tools used in metalworking to create holes in steel and other metals. Annular cutters are different from traditional drill bits in that they only remove the material around the perimeter of the hole, leaving a solid core in the center. This creates less waste and makes the process of creating holes in metal faster and more efficient. Benefits of Annular CuttersAnnular cutters offer a range of benefits over traditional drill bits, including: Faster Cutting SpeedAnnular cutters have a faster cutting speed than traditional drill bits. This is because they only remove the material around the perimeter of the hole, leaving a solid core in the center. This can save time and increase productivity in metalworking projects. Less WasteAnnular cutters create less waste than traditional drill bits. This is because they only remove the material around the perimeter of the hole, leaving a solid core in the center. This can result in a cleaner and more efficient metalworking process. Precise CutsAnnular cutters allow for precise cuts in metalworking projects. The cutting edge of the cutter is designed to create a clean and accurate hole in the metal, without leaving rough or jagged edges. VersatilityAnnular cutters are versatile cutting tools that can be used to cut a range of metals, including steel, aluminum, and stainless steel. They are available in a range of sizes to create holes of different diameters. Uses of Annular CuttersAnnular cutters can be used in a range of metalworking projects, including: FabricationAnnular cutters are commonly used in metal fabrication to create holes for bolts and other fasteners. The precise cuts created by annular cutters can help to ensure that the bolts and fasteners fit securely in the metal. Automotive RepairAnnular cutters are also used in automotive repair to create holes for bolts and other fasteners. They can be used to create holes in engine blocks, transmission cases, and other metal components. ConstructionAnnular cutters are used in construction to create holes for piping and electrical wiring. They can be used to create holes in steel beams, concrete walls, and other materials. Maintenance and RepairAnnular cutters are also used in maintenance and repair projects to create holes for bolts and other fasteners. They can be used to create holes in metal components such as machinery and equipment. Tips for Using and Maintaining Annular CuttersWhen using annular cutters, it’s important to choose the appropriate size and type for the project. It’s also important to follow the manufacturer’s instructions for the best results. To maintain annular cutters, it’s important to keep them clean and sharp. Use a soft-bristled brush to remove any debris from the cutter and sharpen the cutter regularly using a sharpening stone or diamond file. Avoid using water or oil when sharpening annular cutters, as this can damage the cutter. ConclusionAnnular cutters are cutting tools used in metalworking to create holes in steel and other metals. They offer a range of benefits over traditional drill bits, including a faster cutting speed, less waste, precise cuts, and versatility. Annular cutters can be used in a range of metalworking projects, including fabrication, automotive repair, construction, and maintenance and repair. When using and maintaining annular cutters, be sure to choose the appropriate size and type for the project and follow the manufacturer’s instructions for the best results. With the right cutter and technique, you can achieve professional-quality results in your metalworking projects(Click here for the Konetool annular cutters).

©Copyright 2022 Gabriel Ditu

|

|

Admiring the universe |